Overview

We rely on aluminum in our everyday lives—from the phones and computers we use to work and communicate to the electric vehicles we drive. We use over 5.5 million tons of it every year. Aluminum is a critical material for the building blocks of a clean energy economy. As demand for clean technology like solar panels, heat pumps, wind turbines, transmission lines, and distribution infrastructure grows, the International Energy Agency estimates that demand for aluminum will nearly double to facilitate the build-out of the clean energy solutions needed to meet international climate targets. As we use more and more, it’s important now more than ever to ensure that primary aluminum is produced in a clean way.

We now have a once-in-a-generation opportunity to decarbonize a major source of global emissions and fundamentally alter the political landscape in the U.S. for climate mitigation. Aluminum producers—smelters—can change how they manufacture aluminum by using clean electricity and transitioning away from highly polluting carbon anodes. By repowering and modernizing aluminum manufacturing, we can reshore the U.S. industry, revive local communities, and restore thousands of family-sustaining jobs to meet the global demand for sustainable aluminum in the coming decades. Between new federal programs and the increasing buildout of renewable energy, there are creative solutions to securing the low-carbon, affordable energy that aluminum smelters need. The U.S. can be a global leader in clean aluminum and, ultimately, a zero-carbon future.

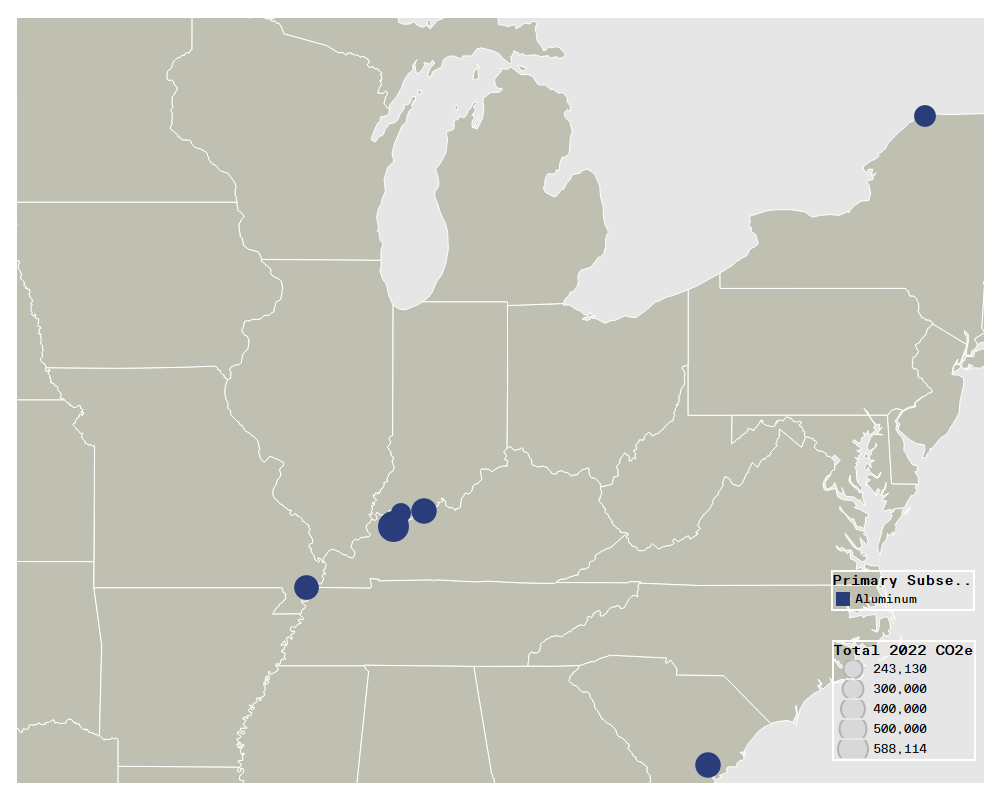

US aluminum smelters

There are only 5 operating smelters remaining in the United States. In 1980, the U.S. produced 30% of the world’s aluminium. Today it produces just 1%.

To learn more about these smelters, visit our U.S. Industrial Facilities Tracking Tool, here.

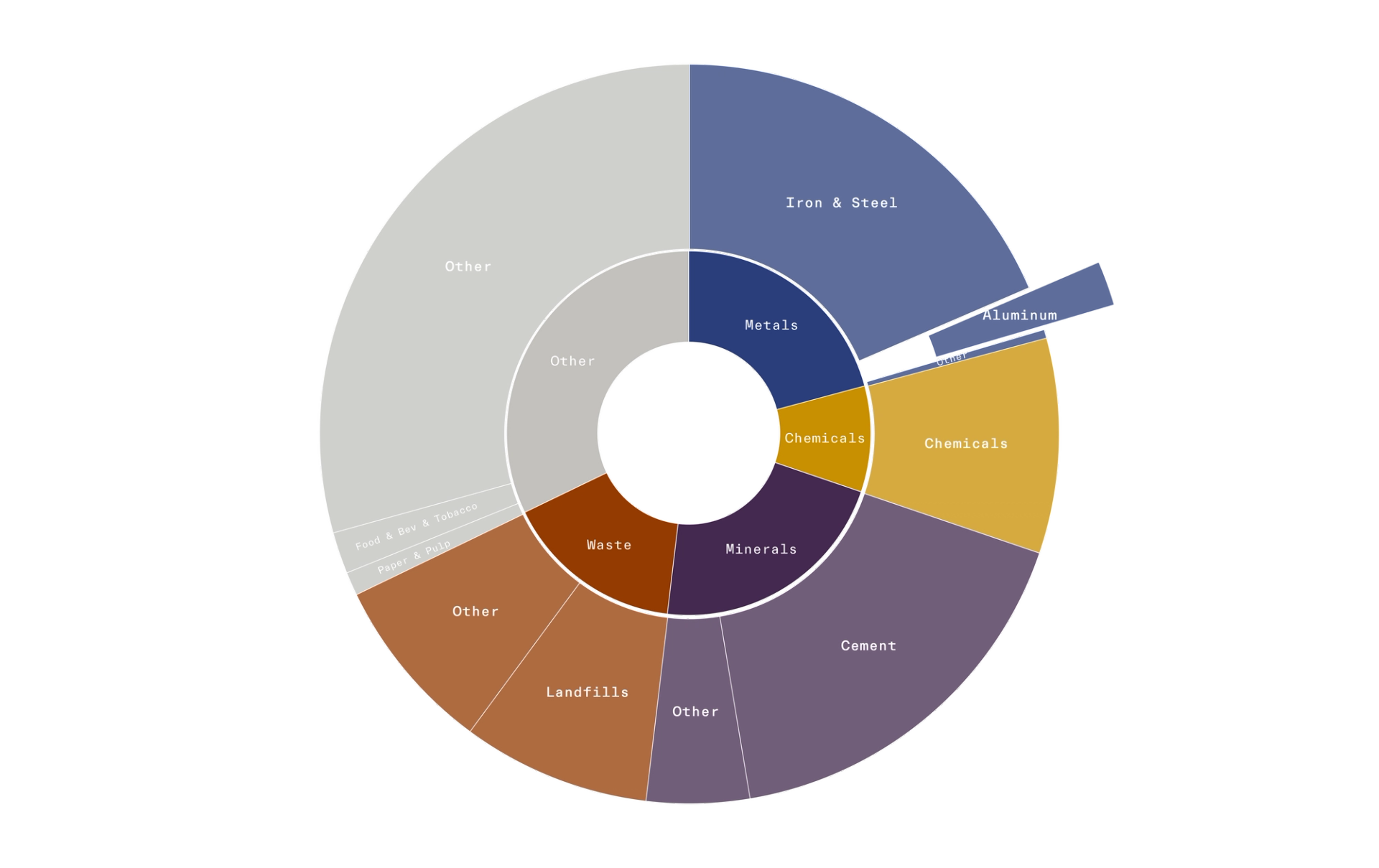

Aluminum industry emissions

Above, the aluminum industry's global emissions relative to other industrial sources. Aluminum production is responsible for approximately 2% of global emissions, largely due to its reliance on coal-fired power plants to supply electricity to the smelters.

Data source: IPCC Sixth Assessment Report, IEA 2022 World Energy Outlook, International Aluminium Institute.

Solutions

Aluminum’s pathway to revitalization is clear, marrying industrial and climate policy. Today, the industry struggles with high costs at aging, polluting facilities. Three critical steps are required.

- Invest in clean energy: ~80% of greenhouse gas emissions and ~40% of the cost of aluminum from fossil fuel-powered smelters stem from electricity. Smelters in states like Kentucky, Indiana, and South Carolina are stuck with increasingly expensive coal power to run their smelters. Helping the aluminum industry access lower cost clean electricity will not only help lower emissions—making our air healthier to breathe, especially communities hit hardest by pollution—but make American facilities more competitive.

- Retrofit smelters: Old and creaking facilities must be modernized, both to improve operations and phase out onsite equipment responsible for additional pollution that sickens communities. Emerging technology will make it soon possible to dramatically lower emissions onsite by phasing out carbon anodes. With $6.3 billion available through the Inflation Reduction Act for industrial facilities, there’s a critical opportunity right now to secure funding to reinvest and clean up our existing facilities.

- Build demand: We use aluminum to make planes, vehicles, solar panels, and so much more. By 2035, the U.S. will require more aluminum than is consumed today, just to make the clean energy facilities needed to meet our climate targets. Early commitments from companies like Ford, Pepsi, solar manufacturers and more will be critical to justifying the major investments aluminum companies themselves must make to reimagine and rebuild the aluminum industry in the U.S.

All of this and more is needed. The good news is that we don’t have to wait to make progress. Clean energy is abundant and available. What stands in the way is state policies restricting clean energy access. The federal government has funding to invest in industrial revitalization. Will the aluminum industry - so critical to our clean energy future and the workers and communities that support these facilities - be prioritized?

Our work

Industrious Labs convenes the Sustainable Aluminum Network—a nationwide coalition working to build a robust, zero-carbon U.S. aluminum supply chain by 2030 by slashing emissions and creating good jobs in hard-hit communities. Through research, policy development, innovative data analysis, and partnering with local community groups, the Network is working to revitalize the domestic primary aluminum industry so it can meet the rapidly growing global demand for green aluminum. Learn about the network here.

Secure policies and funding

Federal investments are necessary to transform the primary aluminum industry and realize a vision of zero-carbon domestic primary aluminum by the end of the decade. There are many opportunities for the U.S. to invest in clean and renewable energy, including aluminum manufacturing. Thanks to the Inflation Reduction Act, the Bipartisan Infrastructure Law, and other policies, U.S. aluminum manufacturers have a historic opportunity to use innovative technologies to upgrade aluminum smelters for the next generation and reverse decades of decline.

Read about the linkage between the IRA and sustainable aluminum here.

Support workers and communities

From regranting to direct support for community benefit agreements and much more, Industrious Labs and the Sustainable Aluminum Network are helping build local capacity for state and local campaigns supporting the decarbonization and preservation of U.S. smelters.

Leverage private sector demand

Big corporations that use aluminum can play a significant role in influencing policymakers to prioritize investments in domestic primary aluminum. We work to deepen our relationships with large private-sector buyers of aluminum to amplify their need for a domestic supply of affordable, zero-carbon primary aluminum. Fortune 500 companies such as Ford, GM, Pepsi, and Ball Corporation are now recognizing this need, too. They signed a letter earlier this year asking for federal investment in clean aluminum. Campaign Director Annie Sartor’s op-ed in Fortune Magazine explains more.