Overview

For decades, steel mills have been the cornerstone of economic power in America's manufacturing heartland, crafting iconic skyscrapers, powering our cars, and propelling the machinery that defines our daily lives. Yet, hidden beneath this industrial strength lies a cost — toxic air and water pollution that adversely impacts nearby communities, deepening the climate emergency.

At the center of this pollution is the blast furnace, a 14th-century technology that burns massive amounts of coke made from coal to make iron and steel. In the U.S., eight facilities clustered around the Great Lakes region still make steel this way. Each facility emits roughly as much carbon dioxide as a coal-fired power plant.

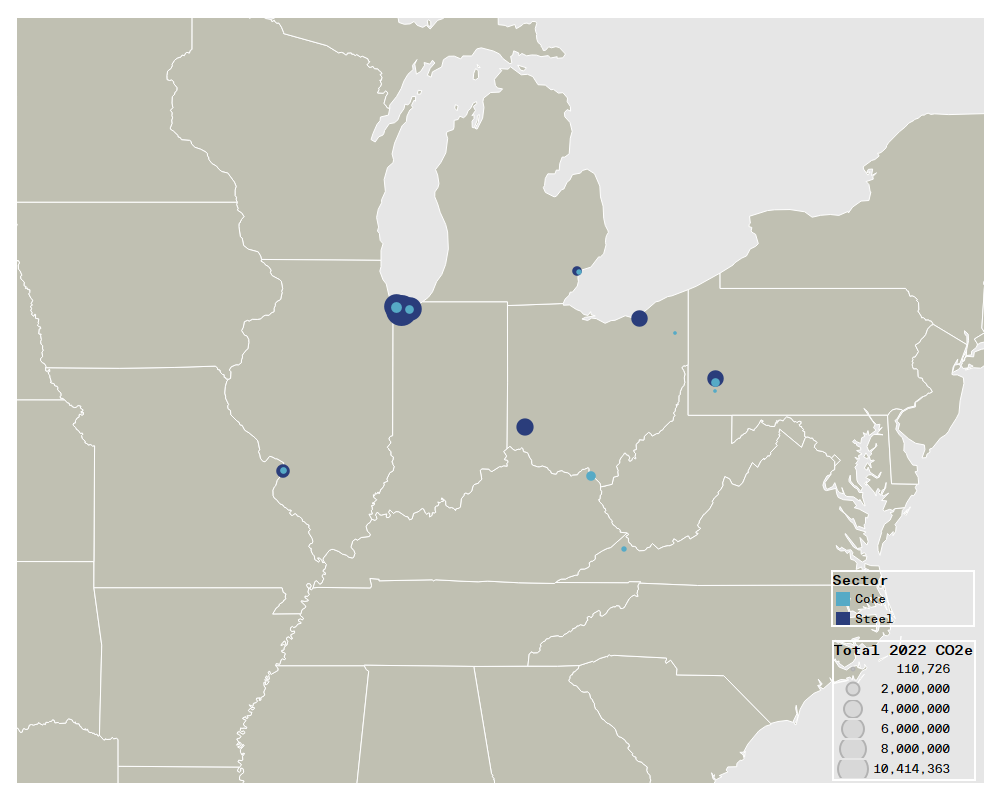

US primary coking, iron and steel facilities

There are eight integrated steel mills in the US, spread throughout the industrial heartland. These facilities use massive quantities of coking coal to produce primary iron and steel, an essential material for the clean energy economy.

To learn more about these smelters, visit our U.S. Industrial Facilities Tracking Tool, here.

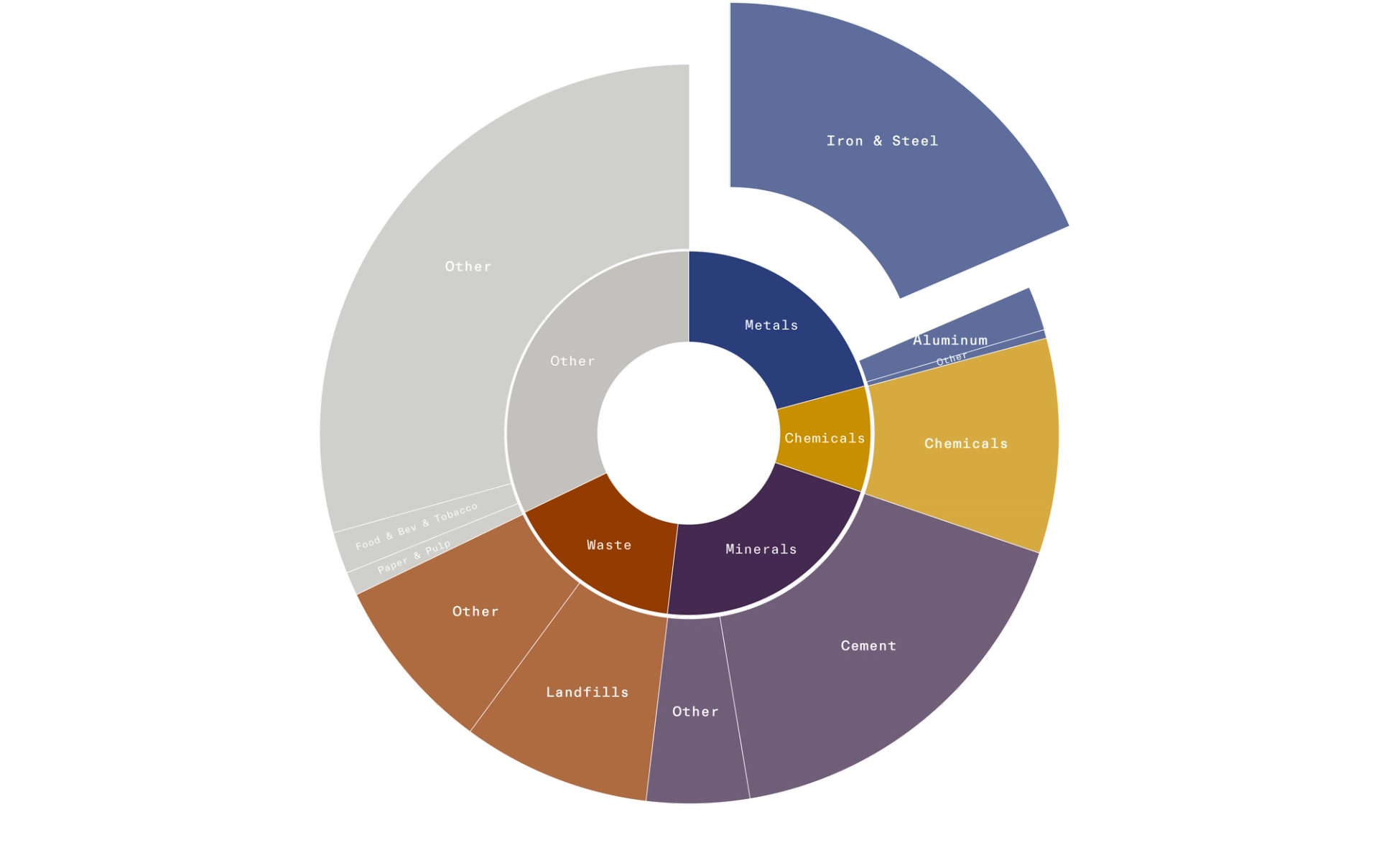

Chart: The steel industry’s contribution to industrial greenhouse gas pollution (scope one), globally.

Globally, steel production is the largest source of climate pollution within industry. When upstream emissions from coal mine methane are included, the sector contributes a whopping 11% of global anthropogenic emissions. Data source: IPCC Sixth Assessment Report, IEA 2022 World Energy Outlook, World Steel Dynamic.

Solutions

The good news is that fossil-free steel is possible today. A proven method of ironmaking known as direct reduced iron (DRI) can be powered by green hydrogen to produce fossil-free steel. On top of this, newer technologies like molten oxide electrolysis are moving closer to being market-ready.

Regional analysis from Indiana and Pennsylvania show that failure to invest in green steel means risking jobs and economic growth. Our polling from Indiana and Pennsylvania in February 2023 demonstrated widespread support for sustainable steel production, with a vast majority of voters in these states in favor of federal investments in transforming the industry.

Other countries, from Namibia to Sweden, are already constructing green steel plants. However, the U.S. has no plans for new facilities, and existing DRI plants in the US are reliant on methane with no plans to transition to green hydrogen. What’s worse: the industry desperately needs to transition to meet climate goals, but major U.S. steelmakers like Cleveland-Cliffs are investing in retrofit projects, each totalling hundreds of millions of dollars, that will extend the life of dirty, coal-burning steel mills for decades to come. Rather than retire or retrofit, we must reinvest in these mills with new technology that relies on green hydrogen and clean energy. If steel companies fail to seize this moment, the U.S. risks being left behind in the green steel boom.

Our work

The challenge ahead of us is immense, but we are determined to reshape the U.S. steel industry into a world leader in green steel, and we will not back down. We’re leveraging our data and analytics, field building, communications, and campaign chops to:

Demonstrate demand

The automotive industry, responsible for 30% of Cleveland Cliffs' and 22% of U.S. Steel's 2022 sales, is key to steering the steel industry towards sustainability. We’re working with partners to urge major players like GM and Ford to invest in cleaner supply chains through the Lead the Charge campaign. Learn why clean EVs need clean steel from our op-ed in Energy Monitor.

Hold polluters accountable

Through sharp communications, data and analysis and focused campaigns, we’re holding the steel industry accountable for its pollution while uplifting the stories of impacted residents. Learn how iron and steel facilities are some of the worst industrial polluters in the U.S. and how impacted residents are fighting for their right to clean air and water.

Transition facilities

The U.S. steel sector stands at a crossroads. Industrious Labs spearheads the North American Steel Network, collaborating closely with national, state, and local partners and fenceline community members to propel the industry toward the era of green steel. Learn how US steelmaker Cleveland-Cliffs could lock in two decades of pollution by relining its blast furnace in Burns Harbor, Indiana.

Secure funding

Federal investments are crucial to driving the transformation of the primary steel industry. The landmark $6.3 billion set aside for cleaning up heavy industry in the Inflation Reduction Act and Bipartisan Infrastructure Bill can help steelmakers make meaningful investments in green steel. We’re working with our partners to ensure steel benefits from this funding and to catalyze the funding and policies essential to transitioning the industry. Learn how the Department of Energy’s Industrial Demonstrations Program can help begin the transition to clean steel if we seize the moment.