Overview

Concrete is the most ubiquitous construction material on earth. It makes up our roads, bridges, dams, buildings, and more. We use 4.2 billion metric tons of it annually. But concrete’s ubiquity comes at a high cost to our climate and communities. Cement, the “glue” that holds concrete together and its most carbon-intensive ingredient, accounts for 7% of total global CO2 emissions.

The cement manufacturing process hasn’t changed in 200 years. Sixty percent of cement manufacturing emissions come from breaking down limestone in super hot (2400-2650 °F) cement kilns; the other 40% comes from burning fossil fuels – like coal, gas, oil, and waste – to heat the kilns. Burning coal emits air toxics, like NOx, and harms local communities. To get to net zero, though, we need to change what we’re burning and putting into kilns.

The global concrete and cement industries are both vast and complex. There are over 2,600 cement plants in 160+ countries, and while ten multinational companies dominate nearly half of the cement market, only 5% of the concrete market is controlled by the top 30 producers.

Continuing business as usual will lock in emissions for the next several decades, but creating the preconditions for innovation and demand for low-carbon cement will set us on a trajectory for net-zero emissions by 2050.

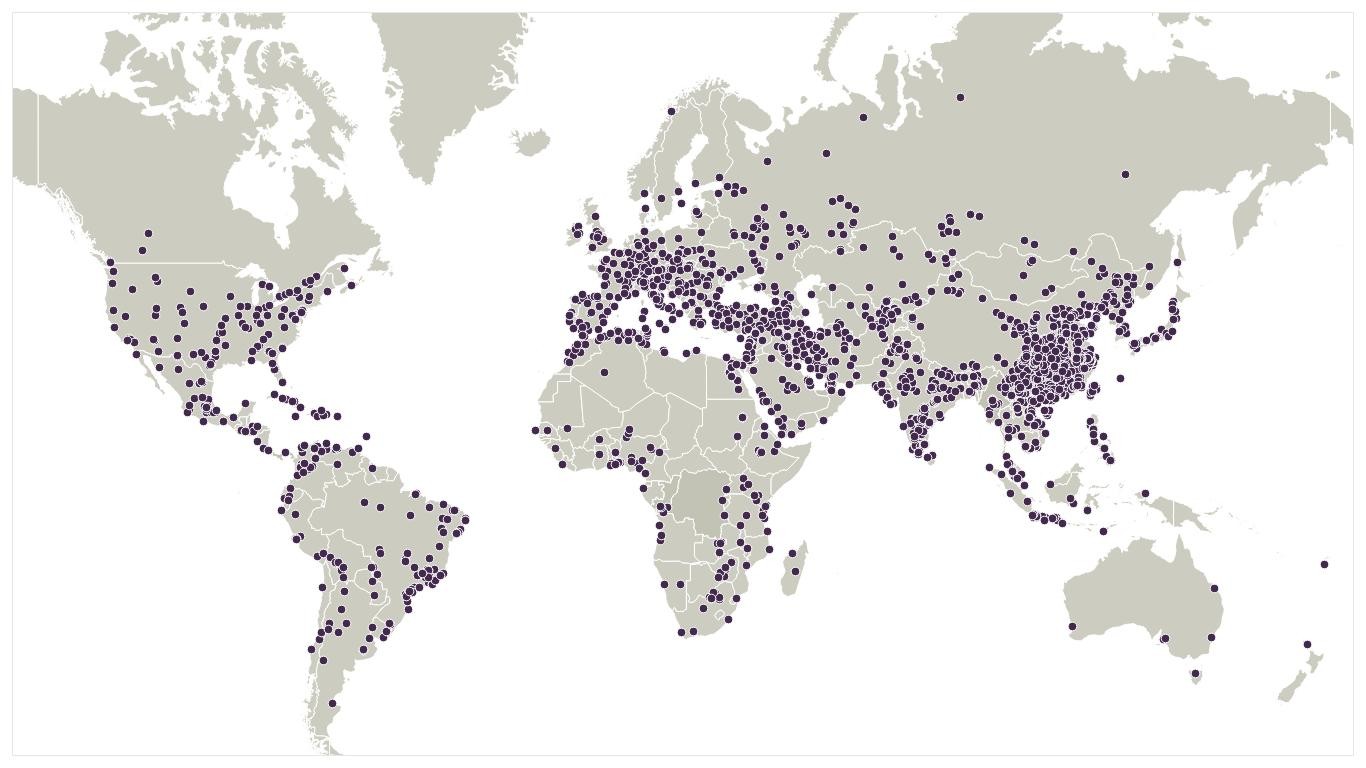

Global cement facilities

Above, a map of the 2,600+ cement facilities in over 160 countries

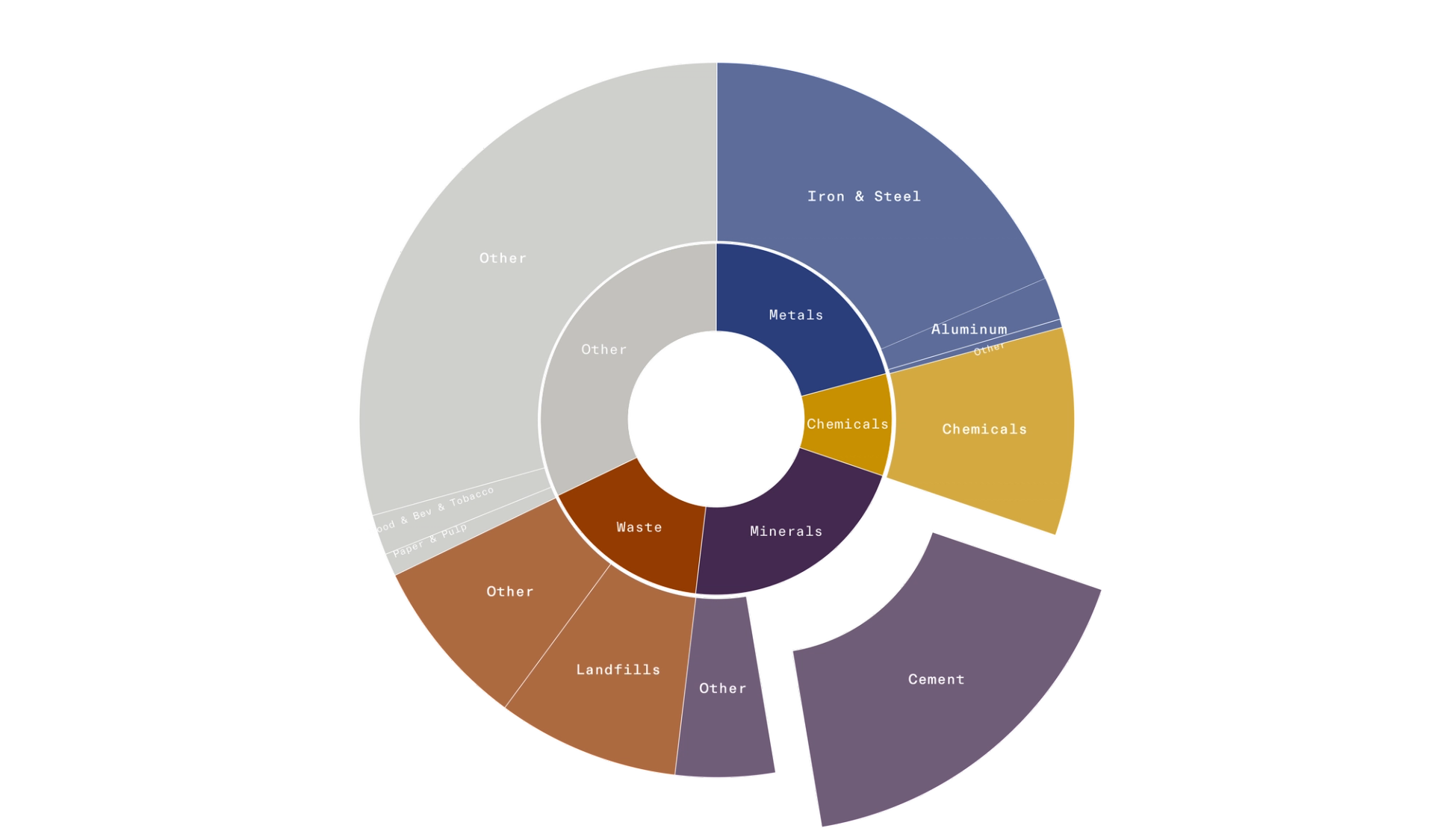

Cement industry emissions

Above, the cement industry's global emissions relative to other industrial sources. Cement production is responsible for over 7% of global emissions. Data source: IPCC Sixth Assessment Report, IEA 2022 World Energy Outlook.

Solutions

Low-carbon cement and concrete solutions exist today, but to rapidly expand their use, they require new policies, standards, and financing. “It is easy to fall into the trap of labeling the industry hard to abate because there is no silver bullet to decarbonising cement and concrete,” says the EU Alliance for Low-Carbon Cement and Concrete. “But a multitude of solutions do exist – and all of them have a part to play in reaching net zero.”

Reducing cement’s carbon footprint is possible today. Blended cements, already widely used around the world, lower carbon emissions by reducing the proportion of clinker in the mix. Additionally, cement manufacturers are implementing new technologies for replacing coal and pet coke with lower-emission fuels, and kiln electrification pilots are already underway.

Demand for cement and concrete is set to increase by more than 33% by 2050, with the majority coming from non-OECD nations. Plants being built now, particularly in the Global South, could operate until the late 2050s or early 2060s – well beyond the urgent imperative to reach carbon neutrality by 2050.

The next 20 years are vital for meeting global emissions targets. As of March 2024, 44 cement producers had targeted net zero by 2050. To meet these goals, producers must start achieving an annual 3-4% decline in the emissions intensity of cement.

Our work

The scale and complexity of the challenge is daunting but not impossible, and the urgency of the climate crisis demands nothing less. This will take a sophisticated and creative campaign to move both domestic and international decision-makers. Fortunately, combining policy savvy, technical expertise, and deep relationships is right up our alley. We’re leveraging our data and analytics, field building, communications, and campaign chops to:

Leverage public sector demand

Governments and financial institutions can pursue policies such as lending requirements and procurement policies to spur innovation and reward leaders. Programs that prioritize low-carbon purchases (like the U.S. Buy Clean Initiative) or policies that disincentivize high carbon projects (like divestment from coal-fired power plants by the IFC) can create important market signals that transform the cement market. We work to deepen our relationships with large U.S. public-sector concrete buyers to amplify their need for a domestic supply of affordable, low-carbon cement, and with large international finance institutions to strengthen their investment plans for low-carbon cement facilities.

Secure funding

In the U.S., federal investments are crucial to driving the transformation of the cement industry and realize a vision of zero-carbon cement by 2050. The landmark $6.3 billion set aside for cleaning up heavy industry in the Inflation Reduction Act and Bipartisan Infrastructure Law can help cement producers make meaningful investments in green cement. We’re working with our partners to ensure cement benefits from this funding and to catalyze the funding and policies essential to transitioning the industry.

Catalyze global leadership

We'll need leaders in key geographies to emerge as vocal champions to bring along the rest of the world. We actively engage local communities who have long been fighting for just development and just climate finance in the Global South. We are building small local networks of local advocates and experts, amplifying their power and voice, and convening them into one larger global network. Through this we are elevating the issue on the global agenda, setting new terms for the cement industry.

Hold producers and purchasers accountable

Both producers and purchasers play significant roles in shaping the cement supply chain. Producers’ actions must align with their pledges to get to net zero by 2050, and that must include setting interim goals to meet IEA’s 2030 carbon intensity target. Purchasers must demand green cement that aligns with company climate commitments and an SBTi 1.5C pathway. We work with both supply and demand side stakeholders to uplift leaders, advocate for incentives, and ensure that players get serious about decarbonization commitments.