Let’s Get Excited About Cleaning Up Food Manufacturing

Evan Gillespie, Partner and Campaign Director, Industrious Labs

Walking down the best aisle at the grocery store (cookie aisle), there’s no shortage of options, even within a single brand: Classic Oreos, Double Stuff Oreos, Golden Oreos, Thin Crisp Oreos, holiday-themed Oreos, and on and on. Perhaps the only kind of cookie you can’t find is one made without fossil fuels. Food manufacturing, in general, uses a lot of fossil fuels—gas in particular—to produce our food. Direct emissions from food manufacturing facilities across the U.S. pollute our atmosphere with roughly 50 million metric tons of GHGs yearly, as much as the entire state of Maryland. When we’re cooking our food, we’re cooking the planet. The emissions impact goes beyond climate, of course. Burning fossil fuels drives soot and smog, and food manufacturing is part of the problem.

The good news is that food manufacturing requires relatively low-temperature heat (no one likes burnt cookies), which means direct electrification of food manufacturing via existing technologies is not only a viable pathway but also addresses climate and health-damaging emissions like NOx and particulate matter. California is home to more than 6,000 food manufacturing facilities, more than any state in the country. With a greening grid, experience with residential and commercial electrification, and a commitment to zeroing out greenhouse gas emissions, the state is in a perfect place to lead the transition to fossil-free food. And, when you combine all this with the fact that the state still has the dirtiest air in the country, the transition to zero-emission food manufacturing takes on added urgency.

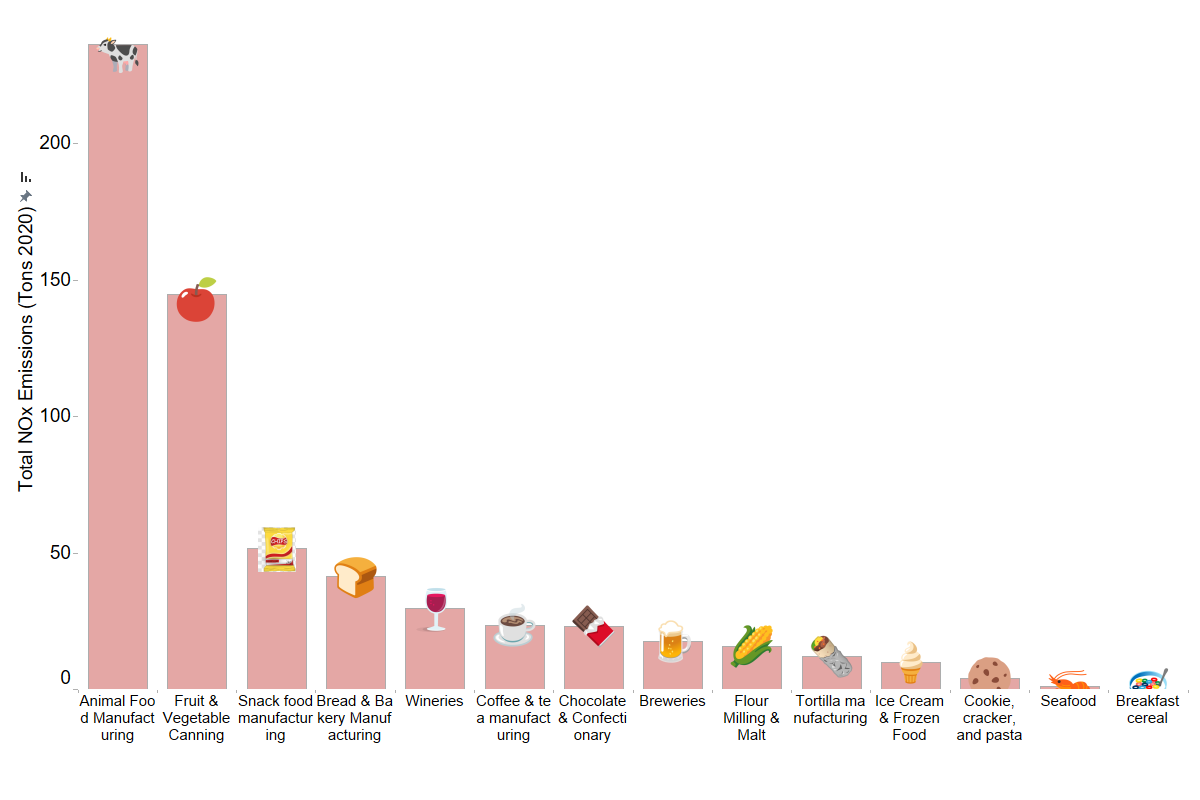

Chart 1: California not only has the most food manufacturing plants in the nation, but a diverse set. Chart 1 illustrates the diversity and NOx impact of the various sub sectors of food manufacturing. Source EPA’s National Emissions Inventory 2020

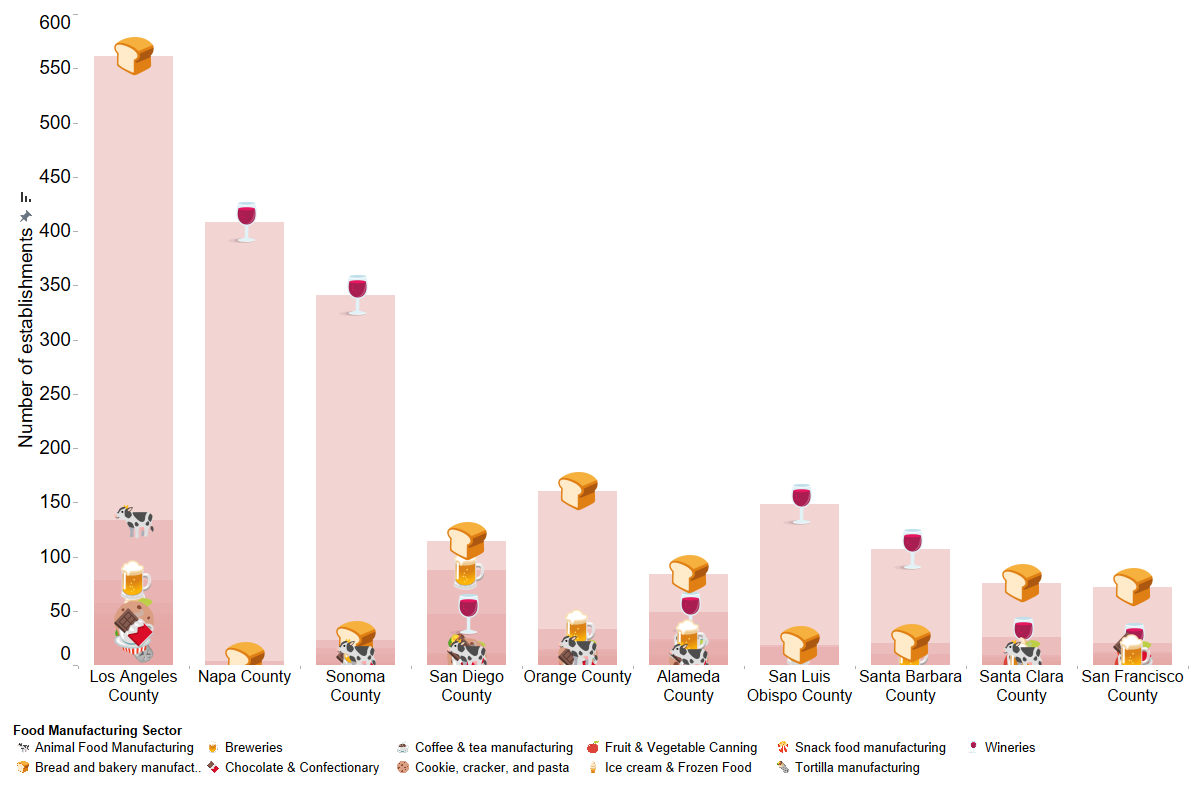

On Friday, the South Coast Air Quality Management District (AQMD), the agency charged with ensuring Southern Californians have clean air to breathe, will take up a vote on a new regulation that cracks open the door to cleaning up food manufacturing. Rule 1153.1 aims to tackle NOx emissions from food manufacturing—in this instance, smokehouses, roasters, bakery ovens, cooking ovens, tortilla manufacturing, and a few other sectors. These are major facilities run by companies like Bimbo Bakeries or Mission Foods that burn large quantities of gas to make bread, tortillas, and more. If you’re in the bread aisle (another good aisle), you’ve certainly seen and probably bought their food. This is a big deal, and Southern California is a great region to show the impact of regulating food manufacturing. Within California, no region has more food manufacturing than Southern California, particularly Los Angeles County.

Chart 2: Los Angeles County has more food manufacturing facilities than any other county in the state, especially bread and baking, which is where SCAQMD is starting its regulatory push. Source: US Census County Business Patterns 2021

The proposed regulation breaks ground in two critical ways. First, it establishes a zero-emission technology requirement (BARCT) for the first time in the state’s history. Past regulatory standards have limited NOx emissions through various pollution reduction technologies but never has an agency established a zero-emission requirement. This is a really big deal! Second, it is proof of concept that we can move to zero emissions in food manufacturing, setting the stage for other facilities: breweries, canned goods, meat and dairy products, and much more. With the South Coast AQMD completing this regulation, Industrious Labs and partners like Earthjustice will be working on a set of other policies to tackle the industrial emissions from food manufacturing.

No doubt, the rule could be stronger; we advocated for shorter compliance timelines and the inclusion of more equipment in the zero-emission standard. Our dream of fossil-free tortillas will have to wait for another day. Nevertheless, this is an important milestone for industrial electrification.

Food manufacturing is a fun corner of industrial decarbonization. In a sense, it is sort of like the transit bus of industrial decarbonization. It’s not the biggest source of emissions, but it’s a gateway to broader electrification. Just as electric buses were an early adopter that accelerated the battery technology needed to electrify dirty diesel trucks, electrifying food manufacturing will drive demand for industrial heat pumps that will serve markets well beyond food manufacturing. It’s great to see regulators taking the sector seriously and highlighting yet another example of why the phrase “hard to decarbonize” is such a misnomer in industry.